New at Schneider: Investment in a new automated small parts warehouse

Since 2022, the long-planned, most expensive single investment for buildings at Schneider has been started. Schneider invests in the Tennenbronn site, despite difficult geographical conditions. 100 blasts were necessary. Over 1,000 truckloads of stones were removed.

The new building construction will avoid the need for more sealed surfaces. Old, poorly insulated buildings in need of renovation were demolished for this purpose and now give rise to a completely new and modern small parts warehouse. In addition, the company gains 30% more production space with this measure.

The new automated small parts warehouse will improve processes internally, increase efficiency and productivity. It is mainly used to store prefabricated semi-finished parts and components such as tips, injection moulded parts and purchased parts for the individual assembly departments of the writing instrument production and to supply them just in time.

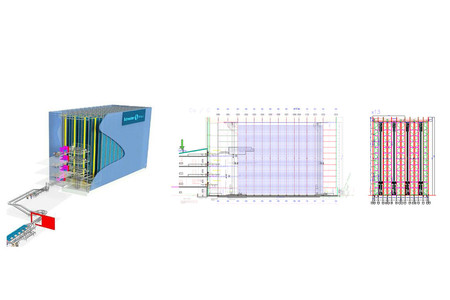

The new building will be 40 m long, 20 m deep and 27,5 m high. There is room for 4 transport aisles for fully automatic conveyor technology into the high racks and up to 65,000 container storage spaces. Each individual container is stored and retrieved fully automatically (without people) by self-propelled electric drive units and roller conveyors from and to the assembly departments located on 4 floors.

The optimum was achieved in terms of fire protection. The oxygen content in the atmosphere of the high-bay warehouse is reduced from 20,9 vol.% to 13,7 vol.% by adding nitrogen. This corresponds to an oxygen content of 3,500 metres above sea level, which is higher than Germany's highest mountain, the Zugspitze. In this atmosphere, even raw materials such as wood, plastic and cardboard can no longer burn because there is not enough oxygen.

Because of the lower oxygen content, only people who have undergone a medical check and training are therefore allowed to enter the building. Visitors cannot enter the premises directly. But they get a glimpse of the ongoings inside through three large glass panes.

Commissioning is targeted for autumn 2023. Schneider is thus continuing its dynamic development and strategic investments and expects further sales growth in future years.

United Kingdom

United Kingdom  Nigeria

Nigeria  Poland

Poland  Turkey

Turkey  Deutschland

Deutschland  Österreich

Österreich  Schweiz

Schweiz  Suisse

Suisse  Italia

Italia  France

France  Argentina

Argentina  España

España  Nederland

Nederland  Belgique

Belgique